Magnesium Head Expander provide vertical test mounting surface larger than the shaker armature provides. They are fabricated from casting or welding ZM5 (equivalent to AZ91) with top and bottom surface flatness and parallelism held to better than 0.15mm. To protect the magnesium, all the base of bolt counter bore holes are fitted with stainless steel washers, pressed into place. To prevent the oxidation, the casting head expander’s surface is anodized. Stainless steel threaded inserts are provided for the specimen mounting.

The magnesium has the characteristics of high specific stiffness and specific strength which are very useful for fabricating shaker head expander. Due to the design of FEMA (Finite Element and Modal Analysis), the head expander can get higher useable frequency with low driven mass to make the shaker output force effective.

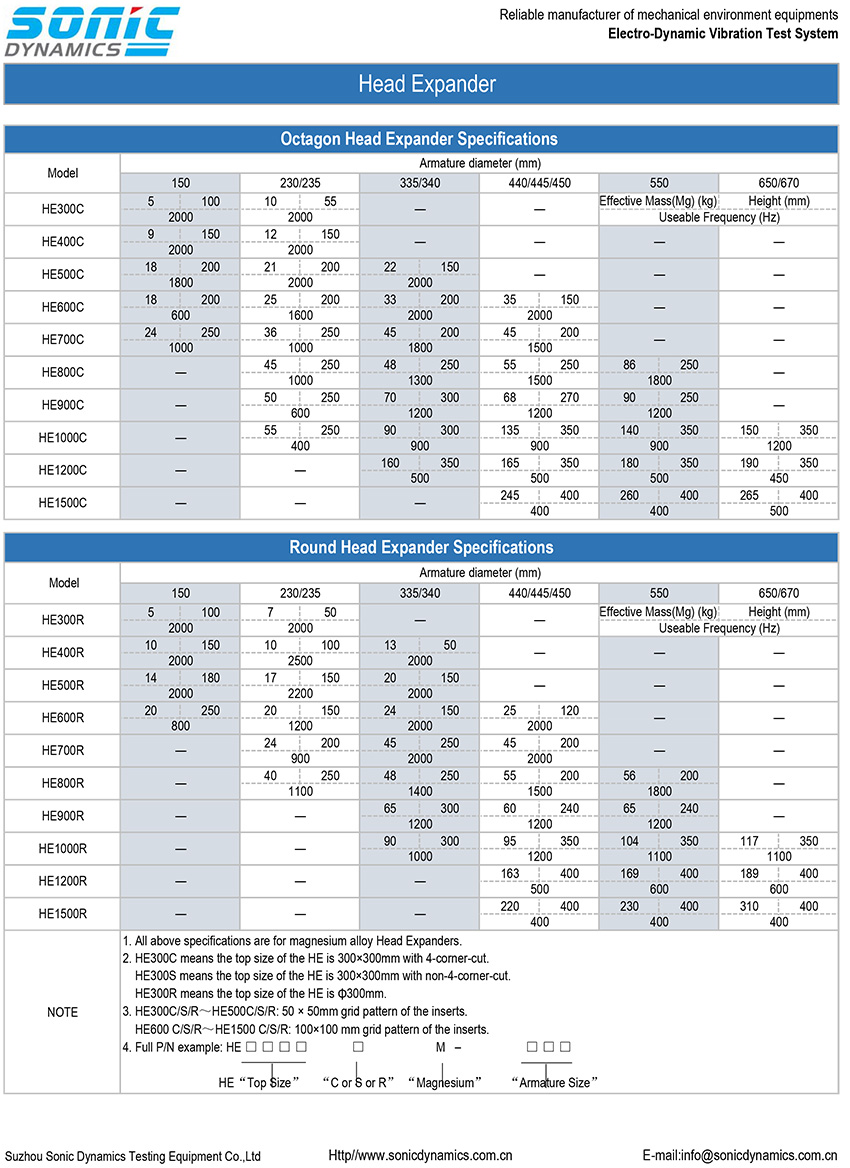

There are three kinds of top surface, octagon, round and square. Due to the flapping of the 4 corners of square top surface, the 4 corners will be cut becoming octagon shape to get the higher uniformity.

Aluminum Alloy is also used to fabricate the head expander in case of the testing need higher useable frequency and the higher driven mass of head expander is not a critical factor.